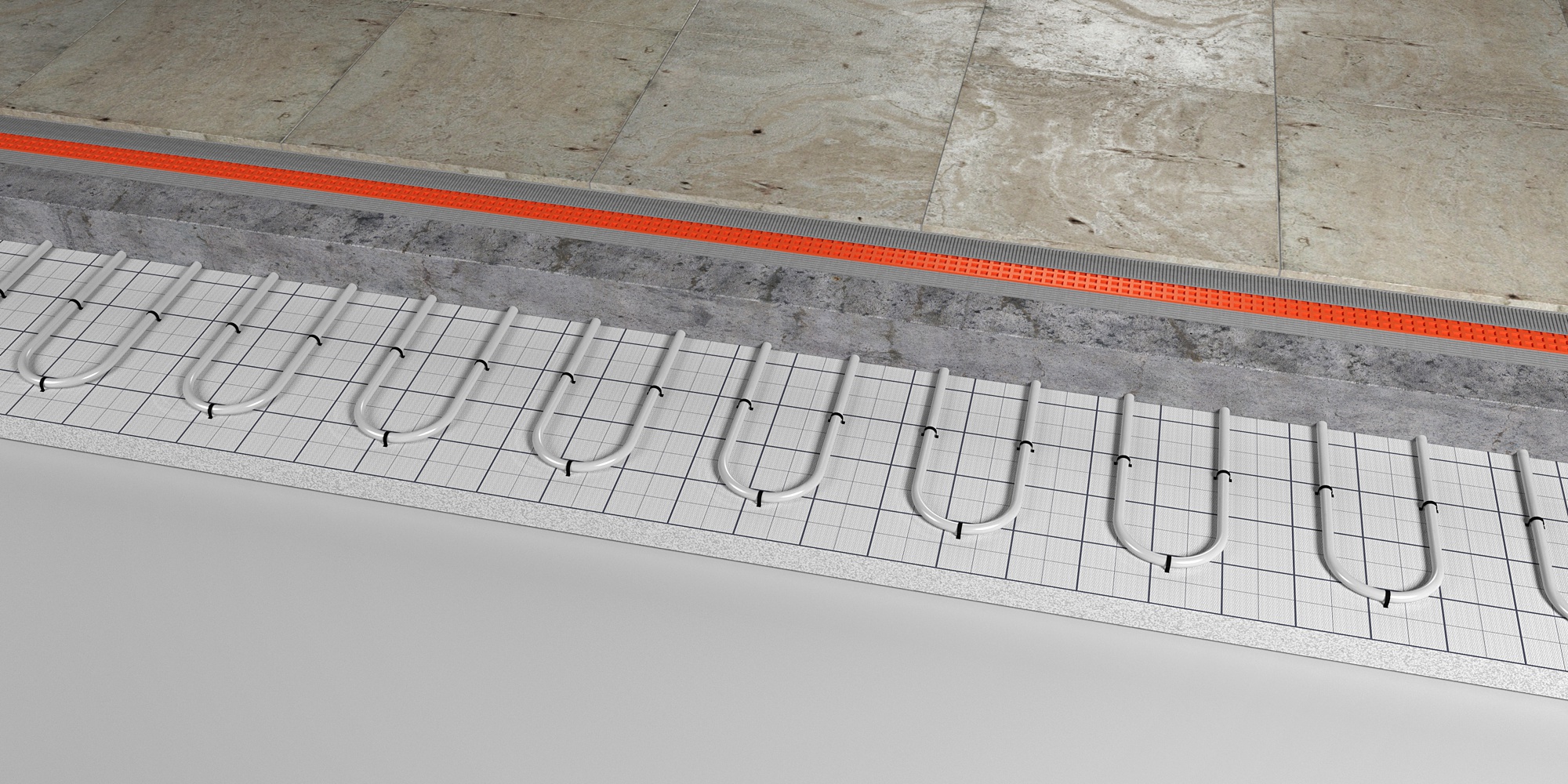

02 | Tacker underfloor heating system

BaseTM Tacker underfloor heating system specifically designed for use within a screeded floor construction, offering design flexibility to accommodate irregular design layouts. The Tacker is a cost effective system offering excellent overall performance.

- Specification

- SYSTEM

- INSTALL

BaseTM Tacker underfloor heating system to incorporate 16mm oxygen barrier pipe to be installed to laminated gridded insulation panel using polymer pipe staples. Staples fixed at 300mm apart. Installation in accordance with pipe layout design. Perimeter expansion edging strip to be installed to perimeter to prevent expansion of screed and thermal bridging.

DOWNLOAD System Specification PDF

SYSTEM

- BaseTM Tacker system specifically designed for use within a screeded floor construction

- Installs directly to a laminated gridded insulation panel to suit specified thermal performance

- Offers design flexibility to accommodate irregular design layouts

- Gridded spacing allows flexible pipe layout to suit exact design requirements

- Pipe staples ensures secure pipe fixing during screeding process.

- Cost effective system offering excellent overall performance

INSTALL

- Laminated gridded insulation panel to be installed to subfloor. Panel depth in accordance with required thermal performance and current building regulations (including membranes)

- Perimeter expansion edging strip to be installed to perimeter with polymer staples ensuring polyethylene skirting is covering sub floor rigid insulation to prevent expansion of screed and thermal bridging

- Oxygen barrier pipe to be installed directly to rigid sub floor insulation at 300mm spacing fixed with polymer pipe staples

- 16mm oxygen barrier pipe to be installed directly to laminated gridded insulation panel in continuous lengths from distribution manifold spaced according to underfloor heating design

- 65-75mm sand and cement screed to be installed (by others) to manufacturers specification

- Pipework to be pressure tested and remain under pressure